Kupanga Zowonjezera Zopangira Ufa Wosapanga chitsulo 316l Ufa Wosindikiza wa 3d

Mafotokozedwe Akatundu

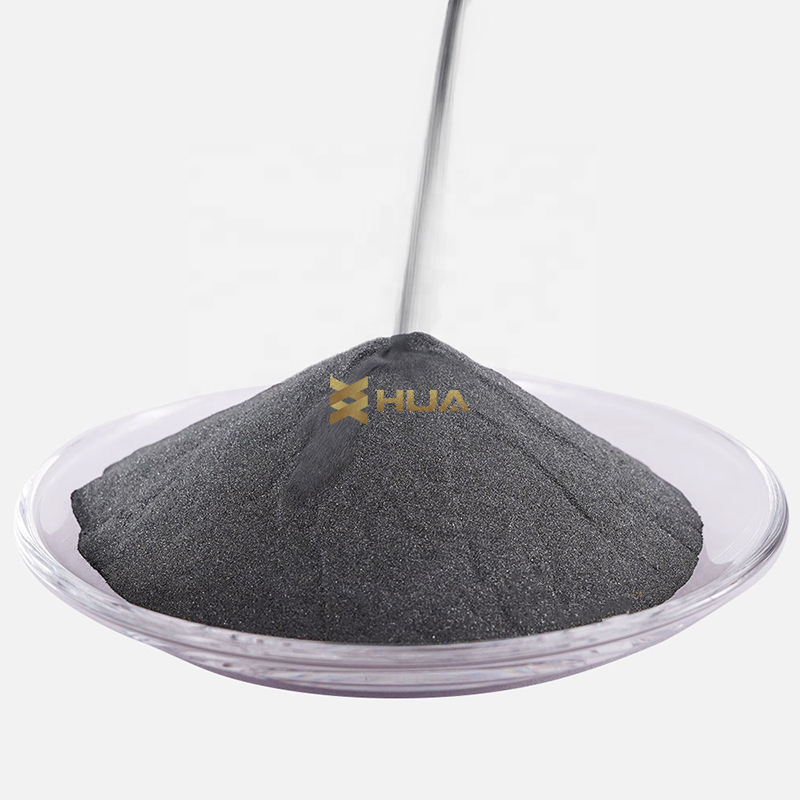

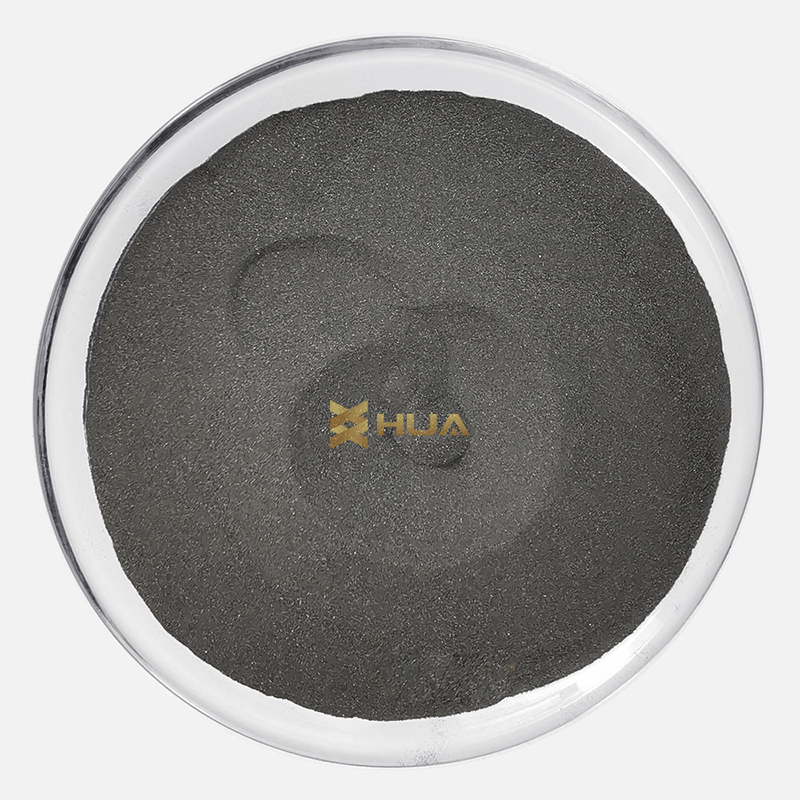

Ufa wachitsulo wosapanga dzimbiri umapangidwa ndi njira ya atomization yamadzi ndipo imakhala ndi kukana kwa dzimbiri komanso kulimba.Ufa wachitsulo wosapanga dzimbiri uli ndi ntchito zambiri zamafakitale.

Perekani mitundu yosiyanasiyana ya zitsulo zosapanga dzimbiri ufa wokhala ndi tinthu tosiyanasiyana.

Malinga ndi ntchito

1.Hot Isostatic Pressing

2.Metal Injection Molding

3.3D kusindikiza

4.Kupopera mbewu kwa kutentha

Malinga ndi kupanga ndondomeko

1.Water atomization

2.Water gasi kuphatikiza atomization

3.Gasi atomization

4.Vacuum atomization

Tsatanetsatane

| Stainess chitsulo ufa wopangidwa ndi% | |||||||||

| Gulu | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303l pa | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304l pa | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316l ndi | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317l ndi | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| Mtengo wa 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| Mtengo wa 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| Mtengo wa 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410l pa | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430l pa | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434l ndi | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4 PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5 PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <= 0.07 | ≤1 |

Kugwiritsa ntchito

Zitsulo zosapanga dzimbiri ufa angagwiritsidwe ntchito kupopera mankhwala matenthedwe, ufa zitsulo, ufa zitsulo atolankhani sintering (PM), jekeseni akamaumba (MIM) sintering fyuluta, etc., madzi atomization mpweya okhutira<4000PPM, gasi atomization<1000PPM.

Ubwino wa HUARUI chitsulo chosapanga dzimbiri ufa

●Ngakhale ufa, zonyansa zochepa

●Kuzungulira kwambiri

● Oxygen yocheperako

● Kuyenda bwino

●Kuchulukirachulukira kwakukulu, kusachulukira kwambiri kwapampopi

●Ufa wopanda dzenje, ufa wochepa wa satellite

Njira yoyendetsera bwino

1.Huarui ili ndi machitidwe okhwima oyendetsera khalidwe.Timayesa zinthu zathu poyamba tikamaliza kupanga, ndipo timayesanso tisanaperekedwe, ngakhale zitsanzo.Ndipo ngati mukufuna, tikufuna kuvomereza gulu lachitatu kuti tiyese.Zachidziwikire ngati mukufuna, titha kukupatsani zitsanzo kuti muyese.

2.Zogulitsa zathu zimatsimikiziridwa ndi Sichuan Metallurgical Institute ndi Guangzhou Institute of Metal Research.Kugwirizana kwanthawi yayitali ndi iwo kumatha kupulumutsa nthawi yambiri yoyesera kwa makasitomala.