carbonyl iron ufa

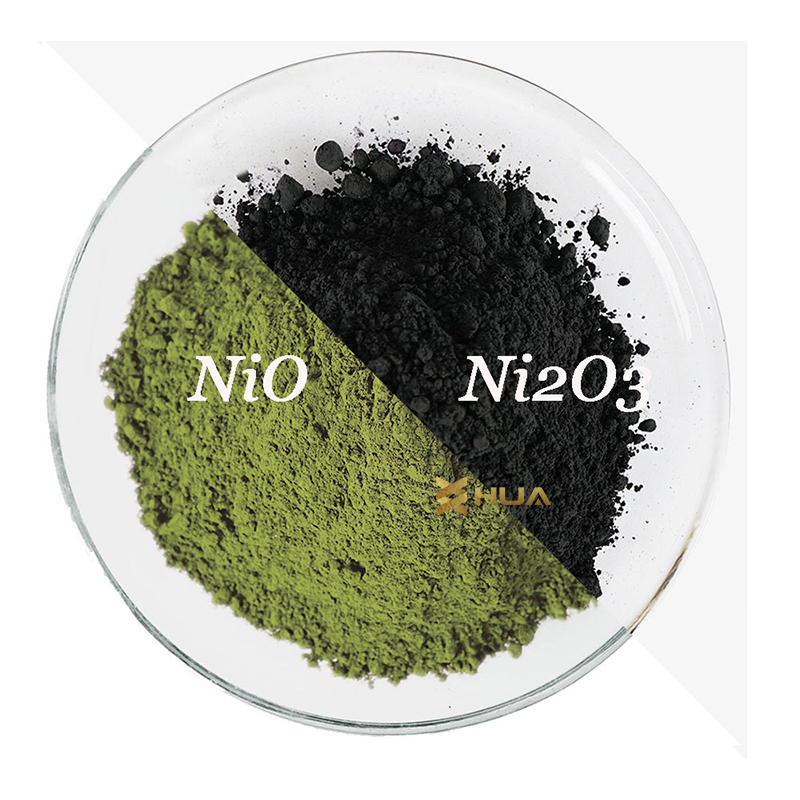

Mafotokozedwe Akatundu

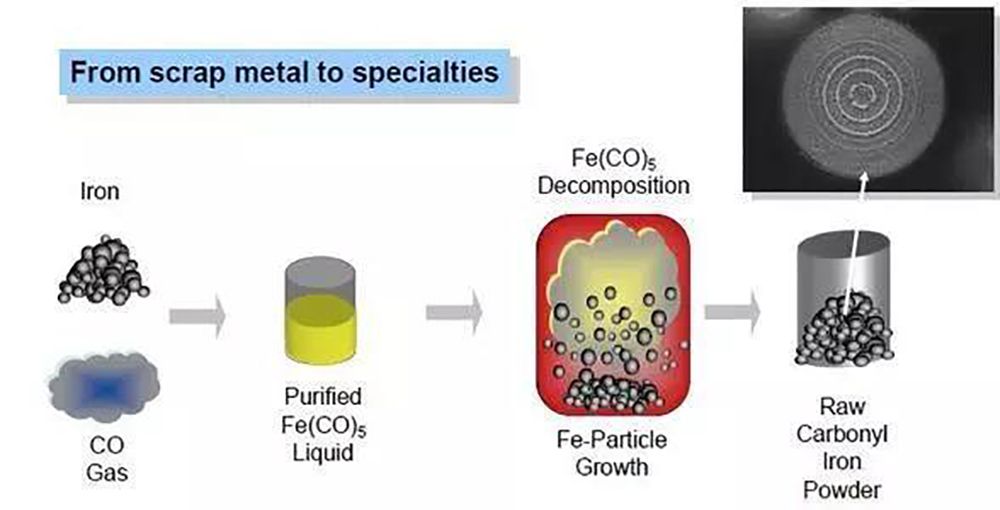

Carbonyl iron powder ndi mtundu wa ufa wachitsulo wapamwamba kwambiri, womwe uli ndi mawonekedwe achiyero chapamwamba, madzimadzi abwino, kubalalitsidwa kwabwino, kuchita zinthu zambiri, ma elekitirodi abwino kwambiri, kukanikiza bwino komanso mawonekedwe a sintering.Mpweya wachitsulo wa carbonyl umagwiritsidwa ntchito kwambiri m'magulu ankhondo, zamagetsi, mankhwala, mankhwala, chakudya, ulimi ndi zina.Mpweya wachitsulo wa carbonyl ukhoza kukonzedwa m'njira zosiyanasiyana monga fiber, flake kapena mpira malinga ndi zofunikira kuti zikwaniritse zosowa zosiyanasiyana za makasitomala.

Kufotokozera

| Kanthu | Chemical Composition | Katundu Wakuthupi | |||||||

| Fe | C | N | O | APP.Kuchulukana | Dinani Kachulukidwe | Laser Particle Kukula | |||

| ≥ % | ≤% | ≥ | ≥ | D10 | D50 | D90 | |||

| HR1-1 | 98 | 0.8 | 0.6 | 0.4 | 2.2 | 4 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR1-2 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.9 | 0.6-1.5 | 2.0-3.0 | 4.5-8.0 |

| HR1-3 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.8 | 1.0-3.0 | 3.0-5.0 | 5.0-12.0 |

| HR1-4 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 1.5-3.5 | 5.0-6.0 | 11.5-16.5 |

| HR1-5 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.0-4.0 | ≥6.0 | 44915 |

| HR1-6 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 4 | 1.5-2.5 | 3.0-4.0 | 5.5-8.5 |

| HR1-7 | 98 | 0.8 | 0.7 | 0.4 | 2.5 | 4 | 2.0-3.6 | 4.0-5.0 | 7.0-11.0 |

| HR1-8 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.6-4.0 | 5.0-6.0 | 11.5-14.5 |

| HR2-1 | 99.5 | 0.05 | 0.01 | 0.3 | 2.5 | 3.8 | 0.58-1.5 | ≤3.0 | 4.5-8.0 |

| HR2-2 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 0.9-3.0 | 3.0-5.0 | 5.5-12.0 |

| HR2-3 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 1.5-3.0 | 5.0-8.0 | 10.0-18.0 |

| HR2-4 | 99.5 | 0.1 | 0.05 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-5 | 99.5 | 0.4 | 0.2 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-6 | 99.5 | 0.05 | 0.01 | 0.4 | 2.5 | 3.8 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR2-7 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 1.5-3.0 | 3.0-5.0 | 5.5-11 |

| HR2-8 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 2.0-3.5 | 5.0-8.0 | 10.0-15.0 |

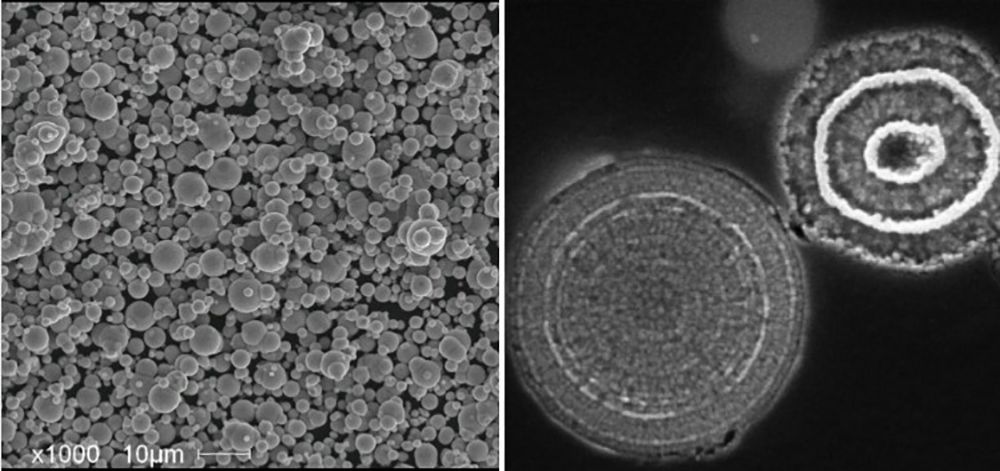

Sem

Ubwino

1.High mankhwala chiyero

2.Zabwino kwambiri zamagetsi zamagetsi

3.Zozungulira

particle, anyezi khungu kapangidwe

4.0.1-10 micron choyambirira tinthu

5.High flowability, dispersibility ndi kusasinthasintha

6.Hgh ntchito, compressibility ndi zabwino sintering katundu